Celina provides our customers contract fabric welding services. We currently offer four types of welding:

Hot Air - Hot Wedge - Ultra Sonic - RF (Radio Frequency)

Each welding process can be used on any thermoplastic material currently available. State-of-the-art equipment and processes are what enable Celina to be efficient and competitive while manufacturing our customers' products.

Forsstrom Traveling RF Welder

Increasing efficiency by reducing material handling, operators work from the Forsstrom Traveling Welder's platform behind the machine and travel with it as it moves along the 5’ x 100’ table. This machine is suitable for both large products with long, straight welds and also products requiring multiple welds in a single area. The programmable gantry travels and completes multiple welds in one pass, maintaining consistent welds via solid state monitoring controls.

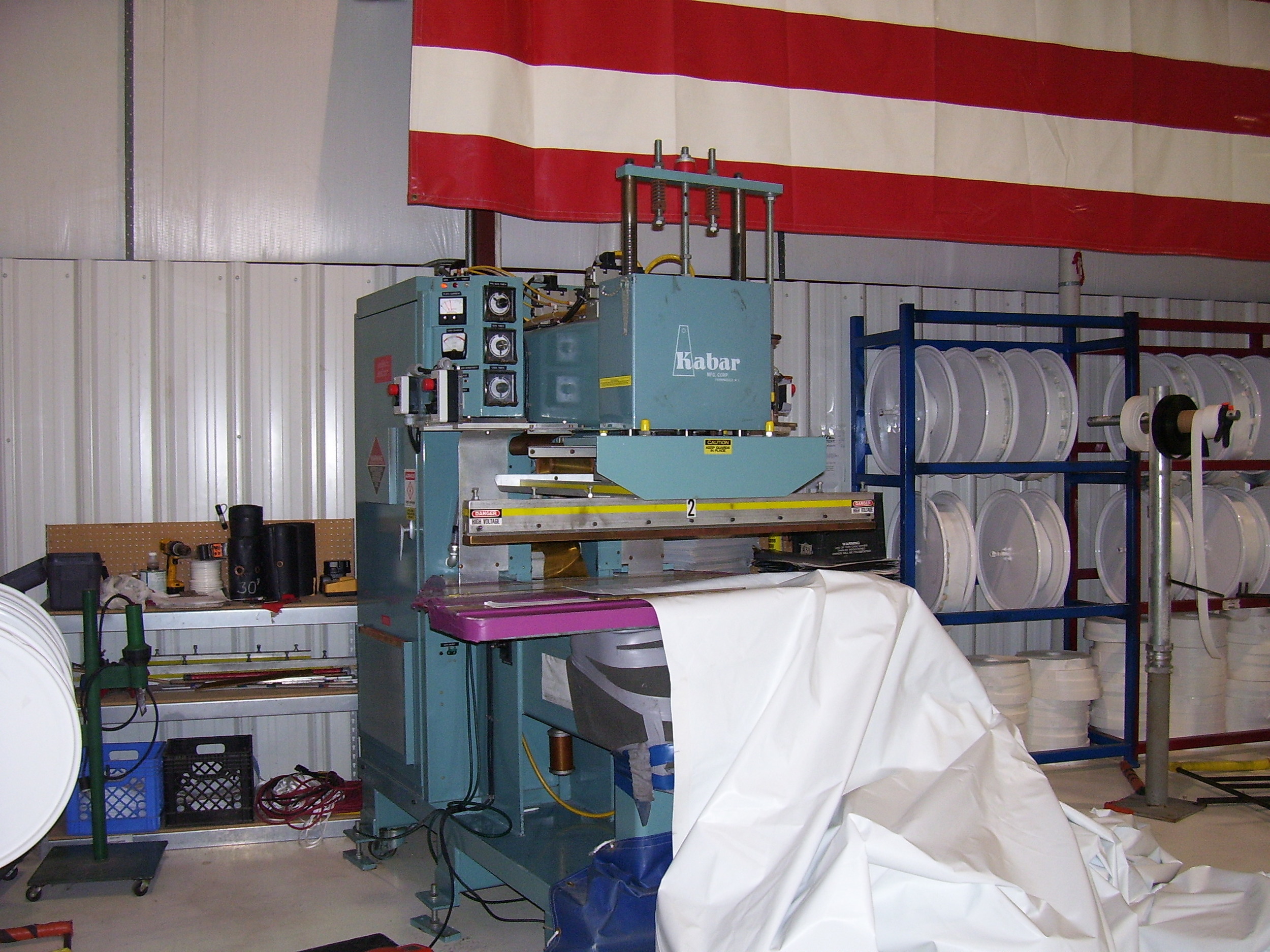

Bar Sealer

The most common RF Welding machine at our facility, the Bar Sealer is equipped with long straight bars ranging from 1” x 13” up to 2” x 48”. This equipment enables us to do long straight RF welded seams of various widths on products difficult to create on other sealing machines.

Platen Sealer

These machines have a large 24” x 48” top plate which allows Celina to place a variety of different die shapes and sizes between the welding bed and the top plate to achieve endless weld shapes. Common uses include attaching reinforcement patches, creating multiple-layer paraphernalia such as expansion joints and door ties, and facilitating small seals that are difficult to make using a larger hot air sealing machine.

MULTI SEALER

The M-100 Multi Sealer has been designed to seal up to 13 hot air seams at once. Developed for high volume, large panel production runs, the machine is equipped with an electromagnetic brake system on the unwind stands, computerized programming and an automatic cutter. The M-100 can also apply supplementary reinforcement materials to sections that may be exposed to excessive stress or wear.

TURNTABLE Sealer

Utilized for large-volume orders, the Turntable Welder has a rotating sealing base to keep work flow moving. Product can be positioned on areas next to the main weld zone, to be moved into the machine as the table spins. Multiple sealers can be moved to utilize a single table, effectively turning Turntable Welders into an RF weld center.

SHUTTLE Sealer

Focusing on production efficiency, Celina’s Shuttle Radio Frequency (RF) Welder allows for automated sealing during a secondary jig loading phase. While the machine is using RF to seal materials together, the operator can safely prep the next piece. The jigs are then swapped, and while sealing the second set the operator removes the finished piece and restarts the process.

Hot air Sealer

Hot Air Welders are used to join thermoplastic industrial fabric and films with hot air and pressure. Temperature settings can range from 1000˚ to 1375˚. Heated air is directed at a pressure wheel, with the combined heat and pressure melding the adjacent layers of fabric. Machine lengths can range from 20’ to 60’, though this doesn't limit the size of the finished product.

Hand Held Heat Sealer

All of Celina’s employees have been trained to use Hand Held Heat Sealers. During this process the worker takes the sealer - which blows hot air out of a nozzle - and places it between the materials they are welding. The sealer is moved down the overlapping material followed by a silicone hand roller, providing the pressure to seal the materials together.

Hand held Ultrasonic Welder

In addition to radio or high frequency (RF/HF) welders, the hand-held Ultrasonic Welder allows us to create small tack welds in a fraction of the time it would take on an RF/HF machine. Compact and portable, the Ultrasonic Welder increases the efficiency of our assembly process by decreasing part alignment on larger welders, and ensuring better product configuration when dealing with multiple layers of materials.

STATIONARY LONG ARM WELDER

Each Stationary Long Arm Welder is used to fabricate heat sealed seams, making reinforced strips on various lengths of material. With an automated material roller to collect finished materials onto spools, this machine conveniently stores strips as they are finished.

SWING ARM WELDER

The T-100 Miller Welder is a hot air welding machine which specializes in creating circular seals. Its adjustable arm allows for straight seams and also for the creation of rounded tubes for items like air ducts.

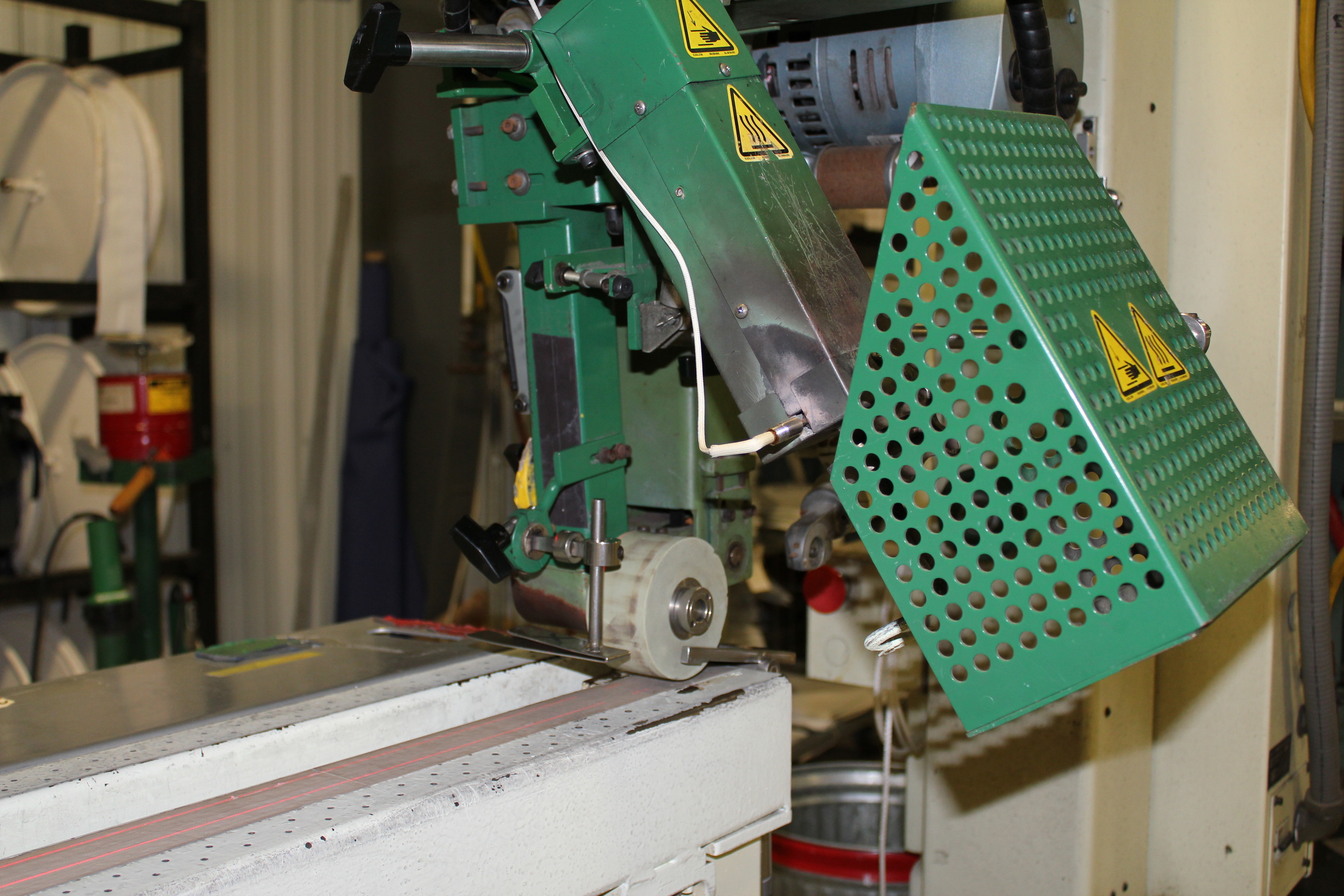

SEWN Seam Taper

This machine lets us attach a layer of heat-bonded tape over sewn seams to increase their ability to be water resistant. Waterproofing seams keeps covered products dryer and increases the overall life of the material by not allowing water into the material layers, thus preventing the growth of mold and mildew.